3d Printer Capability Review

Understanding the Basics of 3D Printing Technology

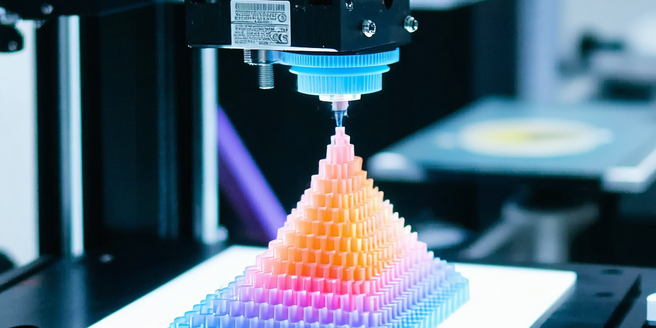

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. It involves laying down successive layers of material until the object is fully formed. This technology has revolutionized the manufacturing industry by offering a fast, cost-effective way to produce prototypes and small batches of products. At the heart of 3D printing is a printer that reads a CAD (computer-aided design) file and transforms it into a physical object. The versatility of 3D printing technology allows for intricate designs and the ability to utilize various materials. As this technology continues to advance, understanding the core principles is essential for businesses and hobbyists alike to harness its full potential and drive innovation across multiple industries.

Exploring the Versatility of Modern 3D Printers

Modern 3D printers have come a long way from their origins, evolving into versatile machines that offer myriad applications across different sectors. These printers can produce complex geometries that were once impossible with traditional manufacturing techniques, enabling innovations in fields such as healthcare, automotive, and aerospace. By leveraging different types of filament materials like PLA, ABS, and metals, users can create customized products tailored to specific needs. Moreover, advancements in printer technology have improved precision and speed, making it feasible to produce high-quality prints rapidly. As the range of compatible materials and technological capabilities expand, the versatility of 3D printers continues to grow, enabling them to take on new roles in product development, prototyping, and functional part manufacturing.

Material Options and Their Impact on Print Quality

Material selection plays a crucial role in determining the quality of a 3D printed object. From plastics such as PLA and ABS to metals and composites, the choice of material will affect the strength, flexibility, and aesthetic of the final product. PLA, for instance, is popular for its ease of use and eco-friendliness, while ABS is favored for its durability and resistance to heat. Advanced users might experiment with materials like nylon or carbon fiber composites to produce specialized parts with unique properties. The impact on print quality also depends on factors like printer settings and environmental conditions. Consequently, understanding the properties of different materials and how they interact with the printer is essential for achieving the desired print quality, whether for artistic projects or functional components.

Comparing Popular 3D Printer Models and Brands

When selecting a 3D printer, comparing models and brands is essential to finding the right machine for your needs. Popular brands like Ultimaker, Prusa, and Creality offer a range of models catering to different experience levels and application requirements. For beginners, Creality’s Ender series is known for its affordability and ease of assembly. Advanced users might prefer Ultimaker’s high-end models, which offer excellent precision and reliability. Each brand provides distinct features such as build volume, layer resolution, and material compatibility. It’s crucial to consider factors like budget, intended use, and required features when comparing options. By doing so, you can identify a model that aligns with your printing goals, whether you’re an enthusiast looking to explore creativity or a professional seeking reliable manufacturing solutions.

The Role of Software in Enhancing 3D Printing Capabilities

Software is a critical component in the 3D printing process, transforming digital designs into printable instructions for the printer. The right software can greatly enhance a printer’s capabilities by optimizing design files and streamlining workflows. Slicing software, like Cura or PrusaSlicer, converts 3D models into G-code, the language printers understand, while enabling adjustments to settings such as layer height and infill density. Advanced software solutions offer features like support generation and error detection, which improve print success rates and reduce material waste. Additionally, software integration in the modeling stage can facilitate complex designs and ensure that they’re structurally sound for printing. As software tools evolve, they continue to expand the creative and functional possibilities of 3D printing, pushing the boundaries of what can be achieved.

Future Trends in 3D Printing and Emerging Technologies

The future of 3D printing is bright, with emerging trends set to further transform industries. One such trend is the development of multi-material and hybrid printing technologies, which allow for the integration of different materials into a single print, enhancing functionality and aesthetic appeal. Additionally, advancements in speed and precision are underway, aiming to make 3D printing more competitive with traditional manufacturing. Sustainable practices are also being prioritized, with bio-based and recycled materials gaining traction. In sectors like healthcare, bioprinting is evolving, paving the way for producing complex tissues and eventually organs. Furthermore, the adoption of AI and machine learning in the design and printing process is poised to optimize efficiency and innovation. As these technologies progress, 3D printing will likely become an integral part of various production chains worldwide.