3d Printers: Beginners Vs. Experts

Understanding the Basics of 3D Printing

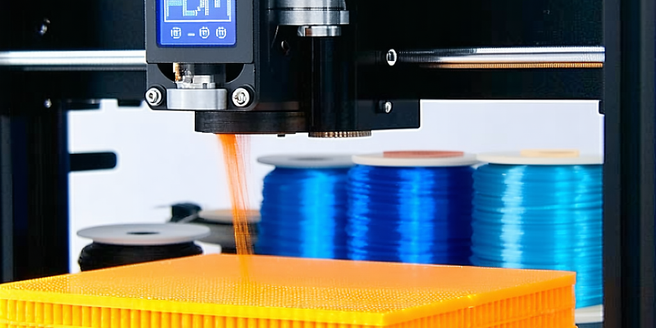

3D printing is a transformative process that allows for the creation of three-dimensional objects from digital files. It involves laying down successive layers of material until the object is complete, a technique known as additive manufacturing. This innovative technology is revolutionizing industries, from healthcare to aerospace, by enabling rapid prototyping and reducing waste. Beginners should focus on understanding the types of 3D printers, such as FDM, SLA, and SLS, and familiarize themselves with CAD software used to design models. Gaining knowledge about materials, such as PLA and ABS, is crucial as they determine the final product’s durability and quality. Additionally, it’s essential to learn about slicing software, which converts digital models into instructions for the printer.

Essential 3D Printing Tools for Beginners

Embarking on a journey into 3D printing demands familiarity with essential tools that aid in producing quality prints. First, having a reliable 3D printer that meets your needs, whether it’s a budget-friendly FDM model or a more precise SLA printer, is crucial. Beyond the printer, beginners should invest in a set of calipers for precise measurements, and a digital thermometer to monitor ambient temperature. Additional tools include a scraper for removing prints from the build plate, and tweezers for handling small parts. Experience teaches that utilizing a glue stick or painter’s tape can improve print adhesion. Finally, software tools like slicing programs are indispensable for converting 3D models into printable instructions. Mastering these tools will greatly enhance the printing experience.

Advanced Techniques for Expert 3D Printers

For seasoned 3D printing enthusiasts, advancing your skills involves exploring sophisticated techniques. Mastery of multi-material printing unlocks new possibilities, allowing for creative designs with varying colors and properties within a single print. Experts often delve into the world of post-processing, where sanding, painting, and even electroplating can elevate a print’s detail and durability. Fine-tuning print settings like temperature and speed will greatly impact the quality and strength of prints, as will experimenting with different infill patterns and densities. Additionally, proficiency in 3D modeling software enables experts to create custom designs, venturing beyond pre-made models. Embracing these advanced techniques not only enhances personal projects but also brings a deeper understanding of this evolving technology.

Common Challenges in 3D Printing for New Users

Newcomers to 3D printing often face a steep learning curve, encountering challenges that can be frustrating and time-consuming. One notable difficulty is achieving the perfect first layer, as this sets the foundation for the entire print. Beginners may struggle with adhesion issues, where prints do not stick to the build plate, leading to failed prints. Troubleshooting and understanding the intricacies of setting the correct temperature and leveling the bed are essential. Another common issue is dealing with filament jams, which require careful filament loading and properly maintained extruders. Unfamiliarity with CAD software may limit design capabilities, while slicing errors can result in prints failing to meet expectations. Addressing these challenges, through practice and research, is key to transforming frustration into successful 3D printing endeavors.

Exploring Cutting-Edge 3D Printing Innovations

In the fast-evolving world of 3D printing, innovations are continually pushing the boundaries of what’s possible. The advent of bioprinting, which involves printing with living cells, holds transformative potential for the medical industry, enabling the creation of complex tissue structures. Innovations like 3D food printing are emerging, offering novel culinary possibilities. Furthermore, advancements in metal 3D printing are reshaping the manufacturing landscape, allowing for the creation of intricate and lightweight parts used in aerospace and automotive industries. Researchers are also exploring self-healing materials, potentially leading to longer-lasting products. Emphasizing sustainability, the incorporation of recycled materials into 3D printing processes is gaining momentum, reflecting an environmental consciousness. As these innovations unfold, they promise to revolutionize both everyday life and specialized fields.

Tips for Transitioning from Beginner to Expert

Transitioning from a beginner to an expert in 3D printing requires a commitment to continuous learning and experimentation. Start by expanding your knowledge of advanced materials beyond basics like PLA, exploring options such as PETG or flexible filaments. Joining online communities can offer support and insights into tackling complex projects. Embracing failure as a learning tool is crucial, as each mistake provides valuable lessons in troubleshooting. Gain proficiency in 3D modeling software, enabling the creation of customized designs. Experiment with different printer settings to understand their influence on print outcomes. Additionally, building a portfolio of diverse projects will showcase your growing expertise. By remaining curious and open to innovation, the transition from novice to expert will follow naturally, paving the way for exciting 3D printing endeavors.