Ai For Predictive Maintenance

Understanding Predictive Maintenance Technologies

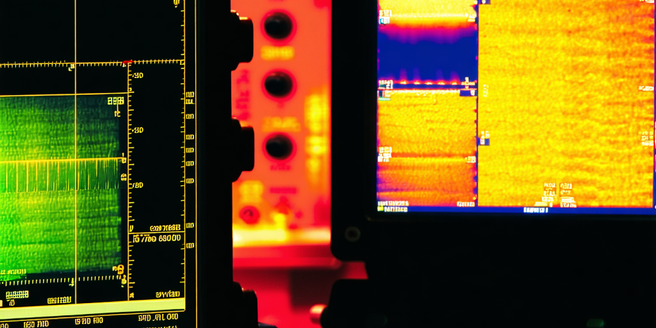

Predictive maintenance technologies are revolutionizing industries by enabling the anticipation of machinery breakdowns and failures. These technologies utilize various monitoring tools and techniques such as vibration analysis, thermal imaging, and oil analysis to detect anomalies and irregularities in real-time. The goal is to shift from routine or reactive maintenance to a more strategic, data-driven approach that reduces downtime and maintenance costs. By understanding the health and performance metrics of equipment, businesses can plan maintenance activities more effectively and increase the lifespan of assets. Integrating predictive maintenance technologies not only optimizes operational efficiency but also enhances safety and reduces the likelihood of catastrophic failures.

The Role of AI in Equipment Prognostics

Artificial Intelligence plays a pivotal role in the field of equipment prognostics by enabling the creation of sophisticated models that predict equipment failures before they happen. AI-driven analytics allow for the processing of large datasets from various sources, providing insights into the future state of machinery. By applying machine learning algorithms to historical and real-time data, AI can identify patterns and trends that human analysis might miss. This proactive approach to maintenance helps in improving reliability, minimizing unscheduled downtimes, and extending the lifespan of crucial machinery. As a result, AI is becoming an indispensable tool in enhancing the efficiency and effectiveness of maintenance strategies.

How AI Models Enhance Failure Prediction

Artificial Intelligence models enhance failure prediction by leveraging machine learning to process and analyze massive volumes of data related to machinery operation. These models can predict potential points of failure by learning from past incidents and identifying patterns that precede breakdowns. By incorporating data from sensors, historical maintenance records, and operational conditions, AI models offer high-level accuracy in predicting when equipment is likely to fail. This precision enables businesses to conduct maintenance operations just in time, avoiding unnecessary expenses and mitigating the risk of unexpected downtimes. Consequently, predictive maintenance becomes more strategic, allowing for better resource allocation and improved operational planning.

Implementing AI-Powered Maintenance Strategies

Implementing AI-powered maintenance strategies involves transforming maintenance operations through the adoption of advanced technologies that harness artificial intelligence. The process begins with the collection and organization of relevant data from various sources such as sensors, equipment logs, and maintenance reports. Once collected, AI algorithms analyze this data to forecast equipment performance and health. Integrating AI into maintenance protocols allows for the precise scheduling of service activities, optimizing labor and minimizing disruptions. Organizations embracing AI-powered maintenance see significant improvements in equipment reliability, reduced downtime, and enhanced productivity. By leveraging AI, maintenance operations transition from reactive or calendar-based approaches to data-driven decision-making.

Real-World Success Stories and Case Studies

Real-world success stories and case studies highlight the transformative impact of AI in predictive maintenance across various industries. Companies that have adopted AI-driven maintenance strategies report substantial improvements in operational efficiency and cost savings. For instance, global manufacturing firms implementing AI for predictive maintenance have decreased unexpected equipment failures by up to 30%. In the aviation industry, AI technologies ensure that aircraft are properly serviced and safe for flight, significantly reducing the likelihood of in-flight malfunctions. These success stories underscore the advantages of predictive maintenance in extending the lifespan of machinery, enhancing safety measures, and providing a competitive edge.

Future Trends in AI and Predictive Maintenance

The future of predictive maintenance is poised for exciting advancements as AI technologies continue to evolve. Emerging trends indicate a shift towards more autonomous maintenance processes, where AI systems not only predict failures but also recommend and execute corrective actions. The integration of IoT with AI will further enhance data collection, enabling real-time monitoring and even more accurate predictions. Additionally, advancements in machine learning algorithms will lead to improved models that consider a wider range of variables and scenarios. As industries continue to recognize the value of predictive maintenance, we can expect a broader adoption of AI-driven solutions, setting new standards for operational efficiency and effectiveness.