Digital Twin Technology

Understanding the Basics of Digital Twin Technology

Digital Twin Technology represents the concept of creating a virtual replica of a physical object or system that can be used to simulate, predict, and optimize its real-world counterpart. Originating from NASA’s need to improve spacecraft performance, digital twins enable real-time data feedback, offering a dynamic model that evolves with the physical asset. This technology relies heavily on sensors to gather data and update the digital model, making it more accurate and useful for predictive analytics. By mirroring the real environment, digital twins help businesses in various industries boost operational efficiency, reduce costs, and enhance decision-making. Understanding the fundamentals is crucial for companies contemplating the integration of digital twins into their operations, as it forms the cornerstone of all advancements in digitalization and asset management.

Key Components of a Digital Twin System

A digital twin system is built upon several key components that work in unison to create an effective virtual model. The foundation includes the physical environment which consists of sensors and IoT devices that gather data. This data is conveyed to the digital twin, composed of software capable of processing and analyzing the input to simulate the real-world conditions of the asset. Alongside these are data analytics and machine learning algorithms, crucial for predictive insights and optimization capabilities. Connectivity infrastructure, such as cloud computing and edge devices, supports the efficient data flow between physical assets and their digital counterparts. Ensuring security is also critical, safeguarding data integrity and protecting sensitive information. Collectively, these components create a robust framework that transforms raw data into valuable, actionable insights.

Applications of Digital Twin Across Industries

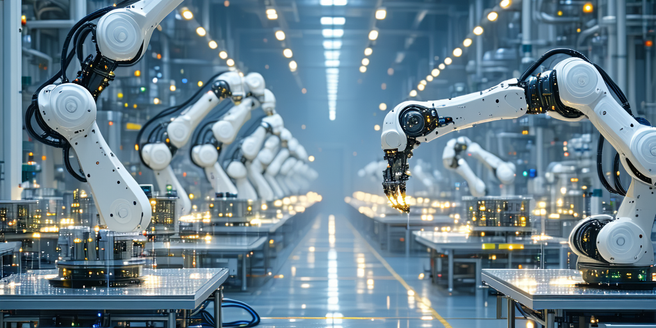

Digital twin technology is transforming numerous industries by offering unprecedented insights and optimization capabilities. In manufacturing, it enhances production processes, improves quality control, and predicts maintenance needs, thereby reducing downtime and costs. Healthcare employs digital twins for patient care optimization, personalized treatment plans, and simulation of medical procedures. Urban planning and smart cities benefit through digital twins by simulating infrastructure changes and managing urban assets efficiently. The technology is pivotal in the automotive industry, aiding in autonomous vehicle testing and vehicle performance analysis. In the energy sector, digital twins enhance the management of power grids and renewable energy resources. These diverse applications underscore the versatility of digital twins, promising extensive improvements in operational efficiency and innovation across fields.

Benefits and Challenges of Implementing Digital Twins

Implementing digital twins offers significant benefits, such as enhanced operational efficiency, predictive maintenance, and improved decision-making. By providing a real-time, dynamic model of physical assets, businesses can optimize processes, reduce costs, and innovate more effectively. Predictive analytics derived from digital twins lead to proactive maintenance strategies, reducing downtime and extending asset life. However, adoption comes with challenges. High initial development costs, data management complexity, and security concerns pose potential obstacles. Ensuring data accuracy and integrity is essential for the reliable operation of digital twins. Furthermore, integrating existing systems with digital twin technology can be resource-intensive, requiring skilled personnel. Addressing these challenges is crucial for organizations to fully leverage the advantages that digital twins offer.

Future Trends in Digital Twin Development

The evolution of digital twin technology is set to advance rapidly, driving significant changes across industries. Future trends indicate a shift towards more integrated and intelligent digital twins, thanks to advancements in AI and machine learning. These technologies will facilitate real-time decision-making, predictive analytics, and autonomous operations. Greater personalization of digital twins for specific use-cases is anticipated, offering tailored solutions to diverse industrial needs. The expansion of IoT and 5G networks will enhance connectivity and data exchange between physical and virtual models, fostering more seamless operations. Additionally, as digital twins become more accessible, even small and medium enterprises can harness their transformative potential. Ethical considerations and data privacy measures will also evolve, emphasizing secure and responsible usage of this powerful technology.

How to Get Started with Digital Twin Projects

Embarking on a digital twin project requires careful planning and strategic execution. Begin by identifying a clear objective, such as optimizing asset performance or reducing maintenance downtime. Next, assess the existing IT infrastructure and determine the necessary technological upgrades needed to support digital twin implementation. Choose appropriate sensor technologies and data analytics tools for accurate data collection and processing. Collaborate with stakeholders across departments to ensure alignment and share expertise. Conduct a pilot program to test the digital twin’s efficacy before scaling up. It’s vital to address cybersecurity concerns, establishing protocols for data protection and privacy. Seeking expertise through partnerships with digital twin specialists or technology providers can significantly aid in the initiation process, ensuring smoother integration and setting the foundation for future success.