3d Printing At Home

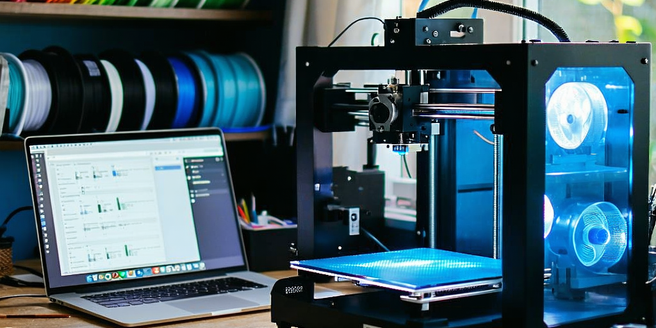

Getting Started with 3D Printing at Home

3D printing at home can be an exciting journey into the world of additive manufacturing. To get started, you’ll first need a compatible 3D printer and a secure space for it. Make sure to choose a printer that fits your specific needs and budget. Delve into online forums and communities where you can seek advice and share your experiences. Familiarize yourself with 3D modeling software options, such as Tinkercad or Fusion 360, which are user-friendly for beginners. Next, explore online libraries like Thingiverse to find and download pre-made models. Ensure safety by reading the manual and observing security guidelines. Calibrate your printer and conduct a test print to verify functionality. With patience and practice, you can create personalized objects right in your home.

Choosing the Right 3D Printer for Your Needs

Selecting the right 3D printer is crucial for a satisfying fabrication experience. Evaluate your printing needs, considering factors like budget, the size of your projects, and the desired material types. Take into account the environment in which you will be operating the printer, as noise and ventilation are also important considerations. FDM printers, known for their affordability and versatility, suit many beginners. If you require high-resolution prints, SLA printers could be ideal, though they generally cost more. Research brands and read user reviews to understand each model’s pros and cons. Check the technical support and availability of spare parts. Matching your needs with the right printer ensures a smooth start to your 3D printing journey.

Essential Materials and Tools for Home 3D Printing

Equipping yourself with the right materials and tools is key to successful home 3D printing. Common materials include PLA, ABS, and PETG, each with distinct characteristics and uses. Choose the one that suits your project requirements. It’s also beneficial to stay updated with the latest advancements in 3D printing technology to maximize your potential. Investing in a good quality 3D printer can significantly enhance your printing results. Other essential tools include a digital caliper for precise measurements, a deburring tool for finishing, and adhesives for assembling parts. A reliable software package for design and slicing can help in efficient model preparation. Additionally, securing spare parts like nozzles and belts ensures minimal downtime. With these materials and tools, you are well-equipped for home 3D printing.

Designing and Downloading 3D Models

Designing your own 3D models opens endless creative possibilities. Software like Blender and AutoCAD allow detailed model creation, catering to both beginners and experts. For those less inclined to design, websites such as Cults and MyMiniFactory offer extensive libraries of downloadable models. It’s exciting to see what you can create with just a few clicks. This digital revolution has democratized creativity, enabling unique personal expression through technology. When downloading, ensure the design is compatible with your printer’s specifications and is in a suitable format like STL or OBJ. Consider licensing and usage terms associated with each model. Experiment with modifying existing models to add a personal touch. Whether designing or downloading, always find inspiration to fuel your 3D printing projects.

Troubleshooting Common 3D Printing Issues

Even experienced users encounter issues, but troubleshooting can often resolve them. Problems like warping can be minimized by ensuring a level print bed and proper adhesion. In some scenarios, switching to a different type of filament could yield better results. In some cases, using a heated bed might also improve results. If layers don’t stick, adjusting the nozzle temperature or speed may help. Clogged nozzles are also common; regular cleaning can prevent this. Poor print quality might stem from incorrect filament storage, so keeping materials dry is advisable. Check software settings regularly and ensure firmware is up-to-date to prevent errors. With a systematic approach, most common 3D printing issues can be addressed, leading to a more enjoyable and productive printing experience.